Supported and partially funded by the Danish state through its Energy, Technology, Development and Demonstration Program, Project Greensand was established to ensure that Denmark can use the storage of CO2 as part of the solution to climate challenges. The project is located in the Danish part of the North Sea, specifically in the Nini field which is situated more than 200 kilometres west of the Danish coast. The Project Greensand sees ScanTech Offshore actively participate to further its market diversification strategy. While the project is still ongoing if deemed successful it will lay the foundation for other international oil and gas operators to actively look at alternative carbon capture storage methods in order to further emission reduction initiatives.

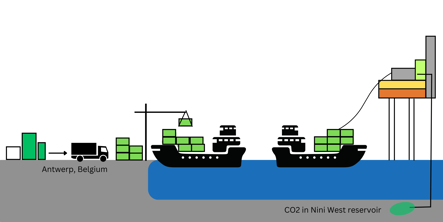

The project started in December 2022 and involves several different Danish and international partners. The scope of the project is to transport CO2 by supply boat in tanks from Antwerp, Belgium, and then bunker the CO2 from the supply boat to an offshore rig. After being transported, the CO2 is injected into the reservoir where it is permanently stored. Each pumping cycle will cover approximately 800m3 of CO2, with up to 14 injection cycles currently planned.

Martin Grimmer, Business development manager at ScanTech OffshoreWhile capturing and storing CO2 has great potential to reduce the amount of CO2 emitted to the atmosphere efficiently and quickly, the challenges associated with injecting CO2 can be complex. Despite the use of proven technology in the form of traditional well test equipment, such as heat exchangers, steam boilers and coiled tubing packages, the size and complexity of the operation is not being underestimated.

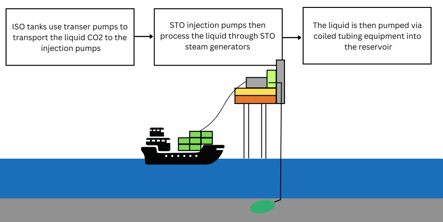

During the process of injecting the CO2, it is pumped at pressure through the ScanTech Offshore heat exchanger, with heat being applied to the processed gas using ScanTech Off shore's steam boilers. This changes its state to a super-critical liquefied CO2, meaning the fluid is held at or above its critical temperature and pressure. The liquid is then pumped via coiled tubing equipment into the reservoir, during which the pressure response in the well is monitored and recorded. On completion the supply boat then returns to Belgium to collect the next batch of CO2, with the whole process typically taking between three and four days between pumping cycles.

The transportation and CO2 injection process.

The CO2 injection process

The First Carbon Storage event held on 8 March was attended by over 300 guests, including His Royal Highness Crown Prince Frederik of Denmark, Danish Minister for Energy, Climate, and Utilities Mr. Lars Aagaard and members of the world press. Another notable inclusion was President of the European Commission Ms. Ursula von der Leyen, who provided her keynote by video.

This marked the first carbon storage for the project and the culmination of its pilot phase, with the final investment decision for a full-scale project planned to take place in the first half of 2024. The goal of the event was to demonstrate the feasibility of cross-border, offshore CO2 storage across the full value chain – from capture to transport and storage.

The Project Greensand if successful will be capable of storing many thousands of tonnes of harmful CO2 indefinitely. ScanTech Offshore looks forward to continuing to follow and assist in the progress of Project Greensand, Denmark’s most mature project for storing CO2.

To read the full press release on Project Greensand’s website, click here.